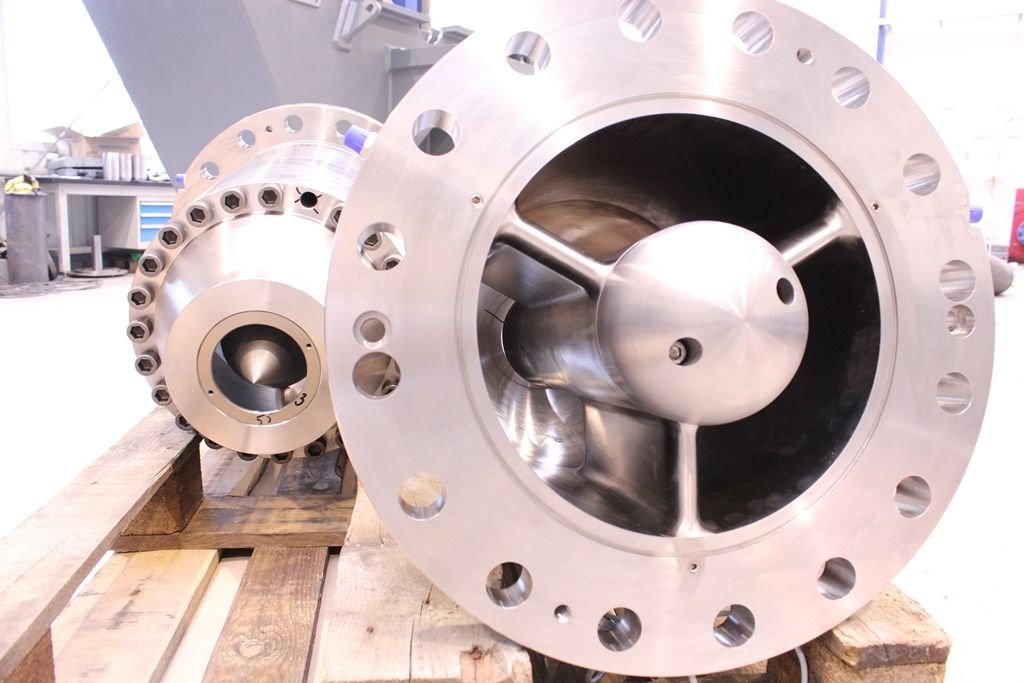

Pelton Turbines

High-head Pelton turbines brought to perfection. High efficiency (90% or more), no water hammer effect, increased safety of operation, stunningly simple installation and maintenance, minimal civil works, and three different layouts (vertical, horizontal and compact-vertical). All tailor-made for every project and exclusively from components from the European Union.

Photogallery

Technology standards

Tailor-made, impulse-type turbine with high efficiency and capability of processing even the lowest partial flows.

Tailor-made

for every installation.

High efficiency

across the entire operation range.

No water hammer effect

And no need for surge valves / surge tanks even very in long pipeline systems.

Low-flow operation

Processing 10% - 100% of design flow and starting operation with just 6%.

Horizontal or vertical layout

Whatever suits the site needs.

Safety closing

mechanism

Deflecting the water stream in case of grid failure and protecting the generator.

Something Extra

Flexible, robust, easy to install and easy to maintain CINK Pelton turbines with higher efficiency and increased safety of operation.

-

Coaxial nozzles

Apart from electric or hydraulic needle nozzles, CINK Hydro - Energy designs its Pelton turbines with coaxial nozzles, taking the already great technology to another level. Slightly higher efficiency, no danger of oil leaking, possible to easily install a blind flange in case one or more nozzles need to temporarily go out of operation. All that for time saving and keeping the unit in uninterrupted production.

-

Safer closing mechanism

If needed, we equip our Pelton turbines with hydraulically controlled deflectors. Valves in the hydraulic aggregate are then set up so that the oil from the cylinders can freely move back into the HPU tank, allowing the deflectors to close no matter what (even when there is a complete, momentary electricity shortage in your power plant).

-

Outer pipe-ring

The water flows into the nozzles and into the turbine via an outer pipe-ring, slightly increasing the overall efficiency and allowing easy access to nozzles in case maintenance is needed.

-

Compact option

Simplified version of vertical Pelton with double-wall design (instead of the more advanced outer pipe-ring) and electric needle nozzles. Perfect for smaller projects or for projects with limited budget.

-

Easily accessible bearings

Easily accessible bearings: Independent runner bearings designed with time-saving and keeping the turbine in production in mind. Feature applicable on horizontal-axis Pelton turbines only.

-

Easily accessible runner

Turbine runner sits on independent bearings and is accessible after removing a simple corner casing from the top. This allows easy access and faster maintenance of the turbine insides whenever needed.

-

Simple installation

Base frame separate from the turbine casing (base frame can be sent to site in advance, making the process of installation approximately 1 month faster).

Furthermore, over the years, we made the installation instructions in the way that any skilled construction company is now able to finish our E&M equipment installation within just a few days. -

Minimal civil works

Besides the separate base frame keeping the civil works time to a minimum, all our Pelton turbines require minimum amount of concrete. Saving your time and money during the construction and installation is one of our priorities and the reason why our clients keep coming back. Contact us, too. Or come and visit and see for yourself. We'll be happy to listen to what it is you need.

Videogallery

Pelton Turbine - Video Brochure

An illustration of our high-head solution in both of the main construction designs - horizontal and vertical.

Watch videoGoran Jablanović about SHPP Kunara

The SHPP operator from Kopaonik Mountains - Mr. Jablanović – introducing a 5-jet vertical Pelton installed right in the center of these remarkable hills near Kraljevo administrative center.

Watch videoInterview (Bílý potok)

Project investor, Mr. Jan Krátký, introducing his high-head power plant located in the south of the Czech Republic, right in the pictorial Bohemian Forest.

Watch video